An interview with Daniel Egger, Department Head Marketing & Sales at Climeworks

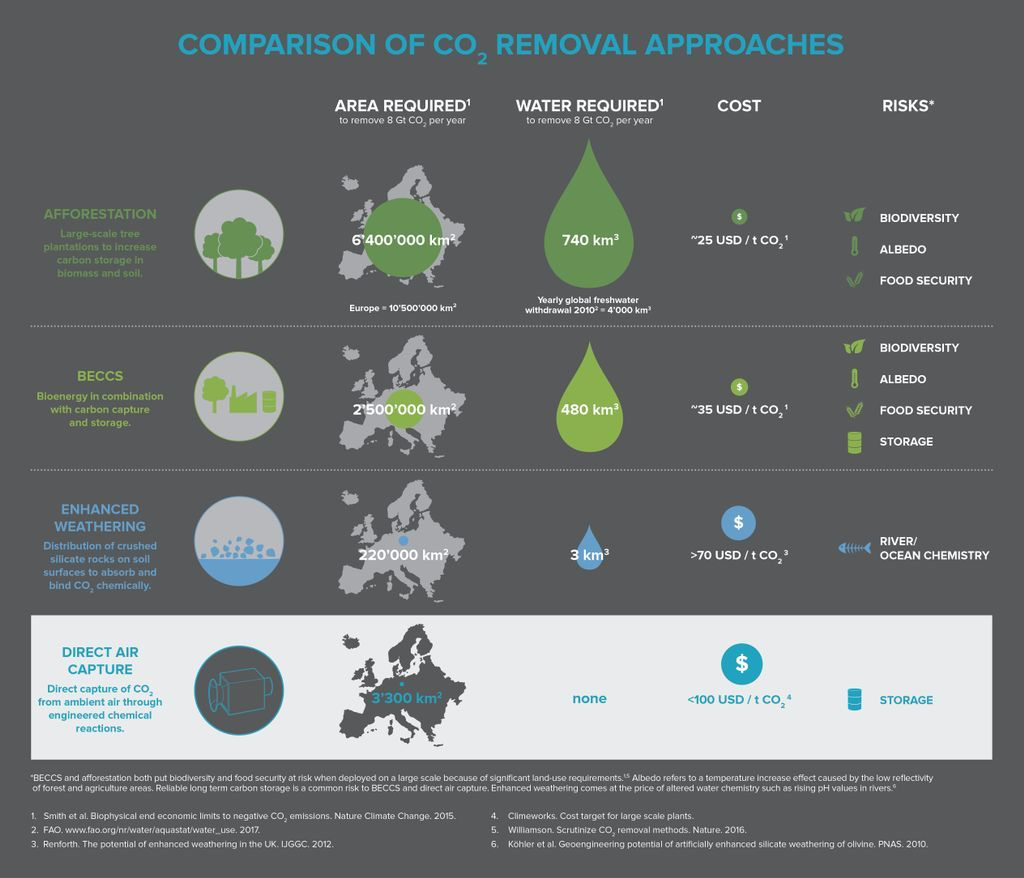

The EU and China have both set ambitious climate targets to reach carbon neutrality by 2050 in the EU and by 2060 in China. To reach this goal in line with the Paris Agreement, the energy transition needs to accelerate and we will need to remove approximately 10 billion tonnes of CO2 per year. Some sectors are notoriously hard to decarbonise, with heavy industry, aviation, and shipping among others contributing up to 27% of global CO2 emissions (Davis et al., Science 2018). One promising solution is to remove CO2 emissions directly from the atmosphere through Direct Air Capture and Storage (DACS). DACS technologies capture CO2 from the atmosphere and store it in natural sinks. It is used in food processing or to provide climate-neutral carbon dioxide for synthetic fuels, also known as Power-to-X (PtX). In Europe, there are currently 220 PtX research and demonstration projects under way or planned. China is also running a number of provincial pilots (Wulf et al., 2020). The immense potential of DACS as a decarbonisation technology is recognised, but financial feasibility and scalability still need to be achieved.

Climeworks, a spin-off from ETH Zurich, is the first company to commercialise Direct Air Capture and Storage technology (DACS) with 14 plants in operation and more in the planning stages. We sat down for a virtual coffee chat with Daniel Egger, head of marketing and sales at Climeworks, to learn about their new carbon removal technology.

Tell us about Climeworks. What does it take to become the world’s first commercial DACS company?

A decade ago, consensus in the scientific community was that DACS would never take off because the concentration of CO2 in the atmosphere is too low. Someone first needed to prove it would work, so there was very little competition at the time. This changed 2-3 years ago, because of new entrants such as Carbon Engineering and Global Thermostat. Now that a number of different companies can demonstrate the potential, it is making real progress.

There are currently 15 direct air capture plants operating worldwide, capturing more than 9 000 tCO2/year. What is unique about Climeworks?

Carbon Engineering and Climeworks offer two different approaches. Carbon Engineering is suitable for larger projects since they focus on building bigger plants and the technology is more complex, whereas we have a modular approach with smaller plants, which allows us to collect more field data and iterate and innovate faster and then scale up later on. We’re convinced of this approach but also appreciate that other methods are in competition with us. The problem is huge and we can’t rely on a single approach.

Climeworks was founded as a spin-off from ETH Zurich. Do universities provide a suitable environment to create innovations? How did you commercialise your revolutionary idea?

Such ideas can probably only work in a research environment and the support universities provide is absolutely crucial. There are a lot of risks at the start and you need freedom to conduct research without the economic pressure to present a business case in the initial stages. It’s important to have an environment where you can test things out with seed money, and to have support from the scientific community.

But it’s also important to step out of this research environment and test the idea in the market. The winner will not be the best technology, but the technology that is commercialised first. You need to be in a competitive environment and compete with other technologies. Carbon Engineering and Global Thermostat provide this necessary competition.

Building a hardware based start-up is much more challenging and capital intensive than a software based start-up. How did you overcome these initial obstacles?

In the scientific environment you’re able to test things out and use existing equipment – that’s important. It is also important to find a way to upscale using as few resources as possible and test out the technology with equipment that’s not capital intensive. Carbon engineering, for example, requires a huge machine to benefit from scaling. We, on the other hand, just need to introduce another collector, test it out, build a multiple of collectors and scale up that way, which saves resources. You also need investors who believe in you. Our founder, Christoph Gebald, says ‘the quota for our investors is not three months but 25 years’. It’s extremely important that they don’t expect a fast return on investment. But also, you need to build plants and identify your first clients, then train your operations to perform. It’s step by step, not a sky rocket.

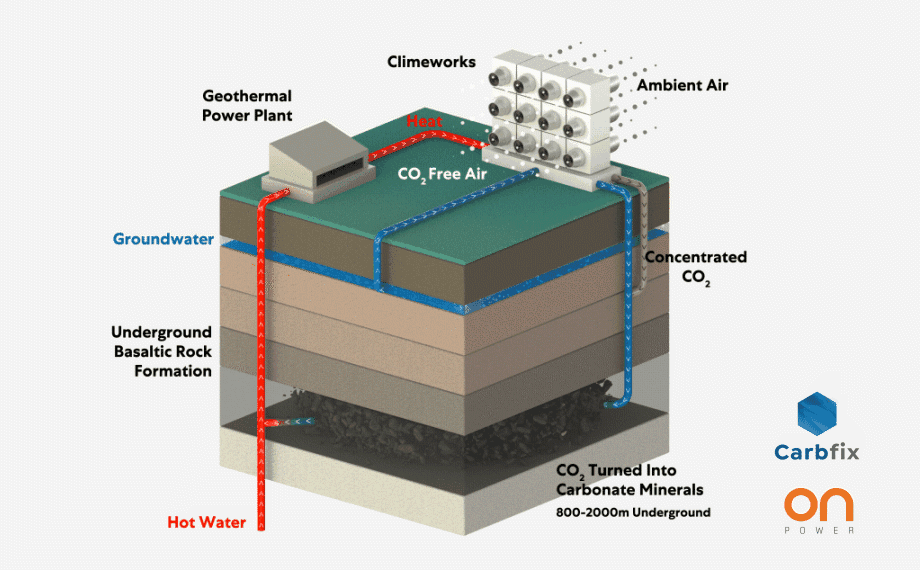

Could you tell us more about the ways to permanently store CO2 and your mineralisation solution (as opposed to storage or sequestration)?

It is not our storage solution; it is a solution developed by Carbfix. So, we have a collaboration. We focus on building the hardware that captures CO2 and they provide the mineralisation solution.

The benefit compared to other solutions is the speed of the mineralisation process. Mineralisation happens everywhere, but very slowly. In a normal reservoir it takes hundreds of thousands of years. Carbfix does it in a few days.

To ensure that the CO2 is not able to escape, an encapsulated volume or reservoir underground is required. We ensure there is an (re)active material there that will react with CO2, such as calcium, magnesium or iron. The third factor is temperature, to speed up the chemical process. With these three elements you get rapid mineralisation.

Could you tell us about other potential uses for the captured carbon, e.g. for carbonating drinks or power-to-X conversion to methane or hydrogen?

There are three main markets:

- The retail market, where there is already a market for CO2, with manufacturers of carbonated drinks the biggest buyers. The market is 30 million tonnes per year, growing 2% per year. The beverage industry and greenhouse industry are our niche markets Other applications, such as the food industry, use it as a protection gas for packaging. There are also smaller medical markets, which aren’t our focus.

- The Power-to-X industry – methane, methanol, synthetic replacement of crude oil, ethanol – a variety of base chemicals which can be upgraded to anything. Power-to-X is probably possible only with DACS because you need to have a very cheap energy source at specific locations where you normally don’t have a carbon source.

- Direct Air Capture and Storage – this needs to be scaled up to 10 billion tonnes by 2050. This is an interesting market for us. Legislation is definitely needed because it’s more costly than alternative solutions. At the end of the day, you’re cleaning the atmosphere which does not have an intrinsic business case, so we need policy support to really scale it up to significant levels.

Could you tell us about the economics of your technology? In another interview you mentioned that you want to bring down costs from 440 EUR to 90 EUR per tonne of CO2. How will you be able to achieve this? How much should a tonne of carbon cost for your business model to be feasible?

Our technology has the potential for cost improvement and this is the first thing we need to work on. Our plants need less energy and are more efficient, use less steel, and improve the sorbent lifetime. Bringing down the cost is the first step.

The second step is to benefit from economies of scale, building bigger plants with bigger components. For example, using a small vacuum pump is more expensive per tonne than when using a larger pump. We’d still be using existing components, but simply bigger.

The third step is mass manufacturing – if you’re able to produce not just one container but hundreds or thousands, you can build them differently and automate the processes. We are focusing on these three steps while learning a lot on the side and expanding the installed base. Overall, we’re taking a traditional approach to bring costs down.

How much should a tonne of carbon cost for the business to be feasible? The price span is huge. For example, in the Netherlands today it can cost EUR 50 per tonne, but there are locations where you can pay over EUR 1,000. In the long term, we’re looking at a price below EUR 200 per tonne. In the short term, mechanisms to close bigger gaps are needed, such as the feed-in tariffs in the PV industry which help to cover a wider cost range at the initial stage.

What policy developments would you wish for over the next few years to help your business grow?

We’re talking about three different mechanisms:

- We need to have a long term price on carbon to secure this business model.

- In the short term there are other mechanisms, such as a feed-in tariff, which would allow us to have a small volume but a big capital close in the beginning and over time you increase the volume while decreasing subsidies. This is necessary to attract investors and capital so that you can show the investors that your cash flow will be stable throughout the depreciation of the plant.

- Mandatory blending ratios. For example, the EU is now discussing a mandatory blending ratio for synthetic or biofuels by 2025. It can range from 1% to up to 14% in the aviation industry. This is needed to speed up development.

You mention that by year 2025 you are aiming for a global roll-out. Could you tell us more about it? Which countries are you targeting for this?

As I mentioned before, by global roll-out I mean the need to bring down costs and produce more prototypes for different locations. Countries we’re targeting for this signal through their policies that they’re open to new climate technologies– definitely North America, especially under the Biden administration. In Europe, we already have projects in Germany, Switzerland, Iceland, and the Netherlands. Outside of this, in the Middle East there is an appetite – a lot of space for renewables and a lot of capital.

Figure 1: How it works

Source: Climeworks (2020)

Difference between Direct Air Capture and Storage (DACS) and Carbon Capture and Storage (CCS)

CCS is used directly at the source to capture concentrated CO2 emissions, such as flue stacks at coal power plants. By contrast, DACS can remove carbon from atmospheric air in virtually any location.

Figure 2: Comparison of different CO2 removal approaches

Source: Climeworks (2020)

Original Article by Helena Uhde and Veronika Spurná